Description

Advanced Welding Solutions for Two-Wheeled Vehicles

Our two-wheeled vehicles production line combines precision engineering with cutting-edge automation to deliver unmatched quality and efficiency. Designed for motorcycles, bicycles, e-bikes, and scooters, our welding systems utilize robotic arms, laser welding technology, and AI-driven quality control to ensure seamless joints and structural integrity. With a focus on scalability, our two-wheeled vehicles production line adapts to high-volume manufacturing while maintaining flexibility for custom designs. Trust our expertise to elevate your production process with speed, durability, and consistency.

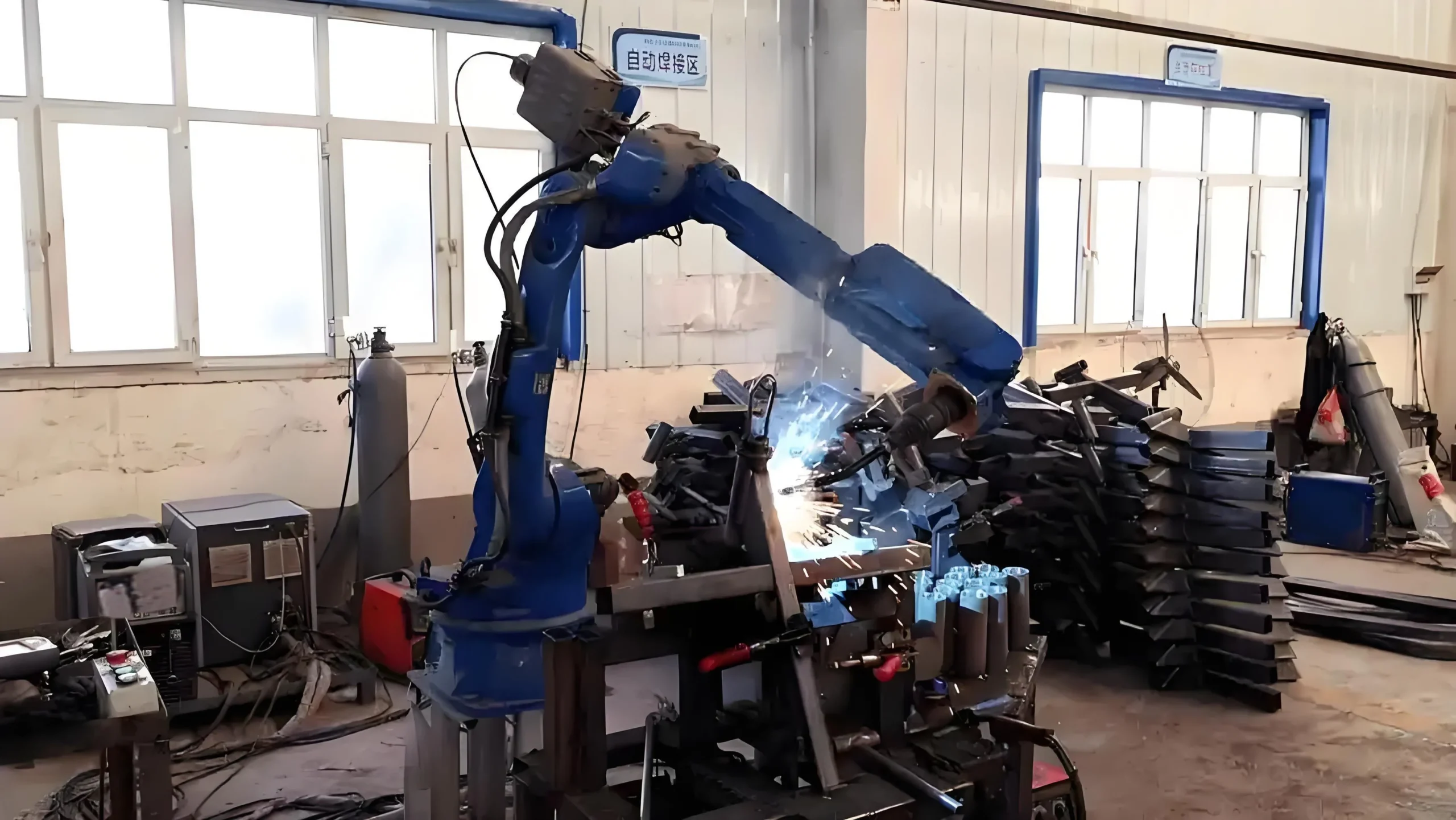

Robotic Automation for Enhanced Productivity

Experience next-generation manufacturing with our fully automated welding lines tailored for two-wheelers. Equipped with 6-axis robotic welders and IoT-enabled monitoring systems, our production line minimizes human error and maximizes output. The integration of real-time sensors ensures precise heat management, weld depth, and material alignment, guaranteeing compliance with global safety standards. Ideal for OEMs and large-scale suppliers, our solutions reduce cycle times by up to 40% while cutting operational costs-empowering you to meet market demands effortlessly.

Customized Welding Systems for Diverse Applications

From lightweight aluminum bicycle frames to heavy-duty motorcycle chassis, our welding production lines are engineered to handle diverse materials and geometries. We specialize in tailored setups, including MIG, TIG, and friction-stir welding, optimized for steel, titanium, or composite alloys. Our team collaborates closely with clients to design workflows that align with specific product requirements, whether for electric vehicle battery mounts or high-stress suspension components. Achieve perfection in every weld with modular, future-proof technology.

Quality Assurance & Sustainable Manufacturing

Quality is at the core of our two-wheeler welding solutions. Each production line incorporates multi-stage inspection protocols, including X-ray flaw detection and ultrasonic testing, to ensure zero-defect outputs. We prioritize sustainability by using energy-efficient welding equipment and recyclable materials, reducing carbon footprints without compromising performance. Certified to ISO 9001 and IATF 16949 standards, our processes guarantee compliance with automotive industry benchmarks, giving your brand a competitive edge in eco-conscious markets.

End-to-End Support & Innovation

Beyond hardware, we provide comprehensive support-from installation and staff training to predictive maintenance powered by AI analytics. Our R&D team continuously innovates, integrating augmented reality (AR) for weld path simulation and machine learning for predictive quality adjustments. Whether upgrading legacy systems or launching a new facility, our turnkey welding solutions ensure rapid ROI and adaptability to evolving industry trends. Partner with us to redefine precision and reliability in two-wheeler manufacturing.