Description

High-Speed Automation for Industrial Shelving

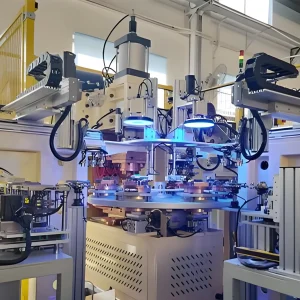

Our steel shelving welding production line combines robotic precision with unmatched throughput, producing up to 1,200 shelving units per shift. Equipped with 6-axis welding robots and AI-driven path planning, it achieves ±0.1mm repeatability on beams, uprights, and braces. Adaptive MIG welding handles materials from 1.5mm cold-rolled steel to 6mm reinforced channels, ensuring structural integrity for pallet racks and cantilever systems. Compliant with ANSI MH16.1 and FEM 10.2.02 standards, the line guarantees load capacities exceeding 5,000kg per bay for heavy-duty warehouse applications.

Modular Flexibility for Diverse Configurations

Designed for mixed-model production, the Steel shelf welding production line seamlessly switches between boltless shelving, mezzanine decks, and mobile rack systems with 15-minute tooling changes. Programmable magnetic fixtures secure components from 300mm to 3,000mm lengths, while laser-guided alignment ensures perfect joint matching for adjustable shelf slots. Optional plasma cutting integration allows in-line customization of perforated panels and safety lips. RFID-tagged components enable traceability across multi-tiered shelving assemblies, reducing assembly errors by 90%.

Smart Quality Control Ecosystem

Real-time weld monitoring tracks 18+ parameters (wire feed speed, shielding gas ratio, interpass temperature) while AI vision systems detect defects like underfill or spatter with 99.7% accuracy. Post-weld processes include automated deburring and powder coat-ready surface finishes (Ra ≤6.3μm). Integrated CMM validation checks critical dimensions against CAD models, generating ISO 9001-compliant certificates for every batch-ideal for aerospace-grade storage systems and pharmaceutical warehouses.

Energy-Efficient Lean Manufacturing

Regenerative power systems and servo-driven conveyors reduce energy consumption by 35% compared to traditional lines. Compact U-shaped layout minimizes footprint by 20%, while overhead gantry systems handle pallets up to 4,000kg. Eco-mode welding generators and VOC filtration units meet EPA Tier 4 emission standards, supporting sustainable manufacturing for green logistics projects. Smart load balancing cuts idle power usage to under 5%, maximizing ROI for high-volume operations.

End-to-End Production Integration

From raw material feeding to final inspection, we deliver turnkey solutions including nesting optimization, weld sequence programming, and lean workflow design. IIoT-enabled predictive maintenance alerts prevent unplanned downtime, achieving 98% operational uptime. Compatible with ERP/MES systems for real-time production tracking, our CE/UL-certified line comes with 10-year durability warranties and ≤0.2% defect guarantees. Backed by global technical support and AWS-certified training programs, we empower shelving manufacturers to slash production costs by 40% while doubling output capacity.