Description

Precision Clamping Solutions for Seamless Assembly

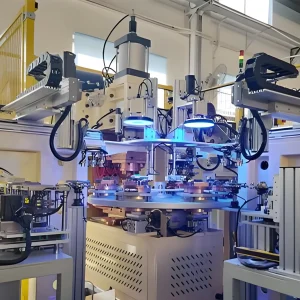

Our Medical bed welding production line employs aerospace-grade aluminum alloys and servo-controlled clamping mechanisms to secure components with ±0.02mm repeatability. Designed for multi-model compatibility (SUV/sedan/electric vehicles), the modular system reduces changeover time by 60% through patented quick-release pins and RFID-tagged tooling. Integrated force sensors prevent part deformation during welding and adhesive curing processes.

Smart Fixturing for Industry 4.0 Production

Equipped with IoT-enabled load cells and real-time positional feedback, our Medical bed welding production line actively monitor assembly tolerances across robotic welding stations. The self-diagnosing system alerts operators about misalignments via HMI dashboards, reducing defects by 45%. Compatible with KUKA/Fanuc robots and MES platforms, these fixtures enable data-driven process optimization for JIT manufacturing.

Ergonomic & Safety-Compliant Designs

Featuring OSHA-certified quick-clamp handles and anti-vibration dampeners, our seat fixtures prioritize operator safety without compromising cycle times. Weight-balanced rotating arms and magnetic workpiece positioning allow single-handed operation, cutting setup time by 30%. All designs meet FMVSS 207/210 standards and undergo 500,000-cycle endurance testing.

Customizable Modular Architecture

From prototype development to mass production, our configurable fixture systems adapt to any seat frame geometry – bucket seats, bench seats, or child safety seats. Interchangeable locator plates and 3D-printed nylon jigs support mixed-material assemblies (steel/Mg alloys/CFRP). Optional laser-guided alignment modules ensure first-time-right positioning for ADAS-integrated smart seats.

Sustainable Manufacturing Integration

Our eco-engineered fixtures reduce material waste by 35% through CNC-optimized nesting algorithms. Corrosion-resistant coatings and regenerative braking systems extend service life by 2X while cutting energy consumption. Compatible with recycled plastics and bio-composites, these fixtures help automakers achieve carbon-neutral production targets without sacrificing precision.