Description

High-Capacity Welding Solutions for Energy Storage Systems

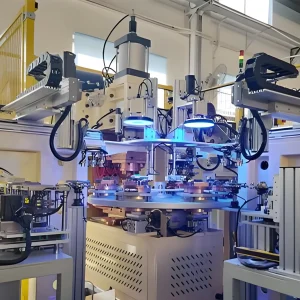

Our energy storage box welding production line combines robotic precision and AI-driven automation to manufacture robust, weatherproof battery enclosures for grid-scale and residential energy storage. Engineered for heavy-duty steel frames and corrosion-resistant aluminum housings, this system achieves ±0.15mm weld accuracy, ensuring airtight seals for IP66-rated enclosures. With adaptive pulsed arc welding and real-time thermal control, our energy storage box welding production linemaintains structural integrity in lithium-ion battery racks and thermal management systems, supporting capacities from 50kWh modular units to 10MWh utility-scale installations.

Multi-Material Mastery for Diverse Storage Tech

Designed to weld advanced materials critical to energy storage-including galvanized steel, marine-grade aluminum, and fire-retardant composites-our energy storage box welding production line delivers UL 9540A and IEC 62619-compliant joints. Proprietary hybrid welding processes eliminate thermal distortion in thin-walled battery trays while ensuring conductivity in copper busbar connections. Our energy storage box welding production lineIntegrated EMI/RFI shielding protects welds in smart inverters and IoT-enabled storage systems, ideal for renewable energy integration and microgrid applications.

Agile Production for Custom Storage Configurations

From stackable residential Powerwalls to industrial containerized ESS, our energy storage box welding production line welding cells adapt swiftly to bespoke designs. AI-powered tool changers switch between laser and MIG welding heads in 75 seconds, while digital twin simulations slash prototyping time by 60%. IoT-connected predictive maintenance and energy recovery systems reduce downtime by 35%, enabling rapid scaling to meet global demand for solar-plus-storage solutions.

Mission-Critical Quality Assurance Protocols

Equipped with 3D ultrasonic testing and automated helium leak detection, our energy storage box welding production line guarantees <0.01% porosity in welds for pressurized thermal runaway vents and coolant channels. Machine learning algorithms analyze 12,000+ data points per enclosure-including vibration resistance and load-bearing metrics-to auto-adjust parameters. Blockchain-secured documentation ensures full traceability for NFPA 855 safety audits and UL 1973 certifications.

Sustainable Manufacturing for Clean Energy Transition

Featuring hydrogen-powered welding stations and closed-loop metal recycling, our energy storage box welding production line reduces carbon footprint by 55% versus conventional methods. Recycled aluminum alloys are transformed into lightweight, corrosion-resistant enclosures for offshore wind storage systems, while solar-powered robotic arms align with net-zero production goals. Partner with us to build the energy storage infrastructure of tomorrow-where durability meets eco-innovation.