Description

Mission-Critical Welding Precision for Elevator Safety

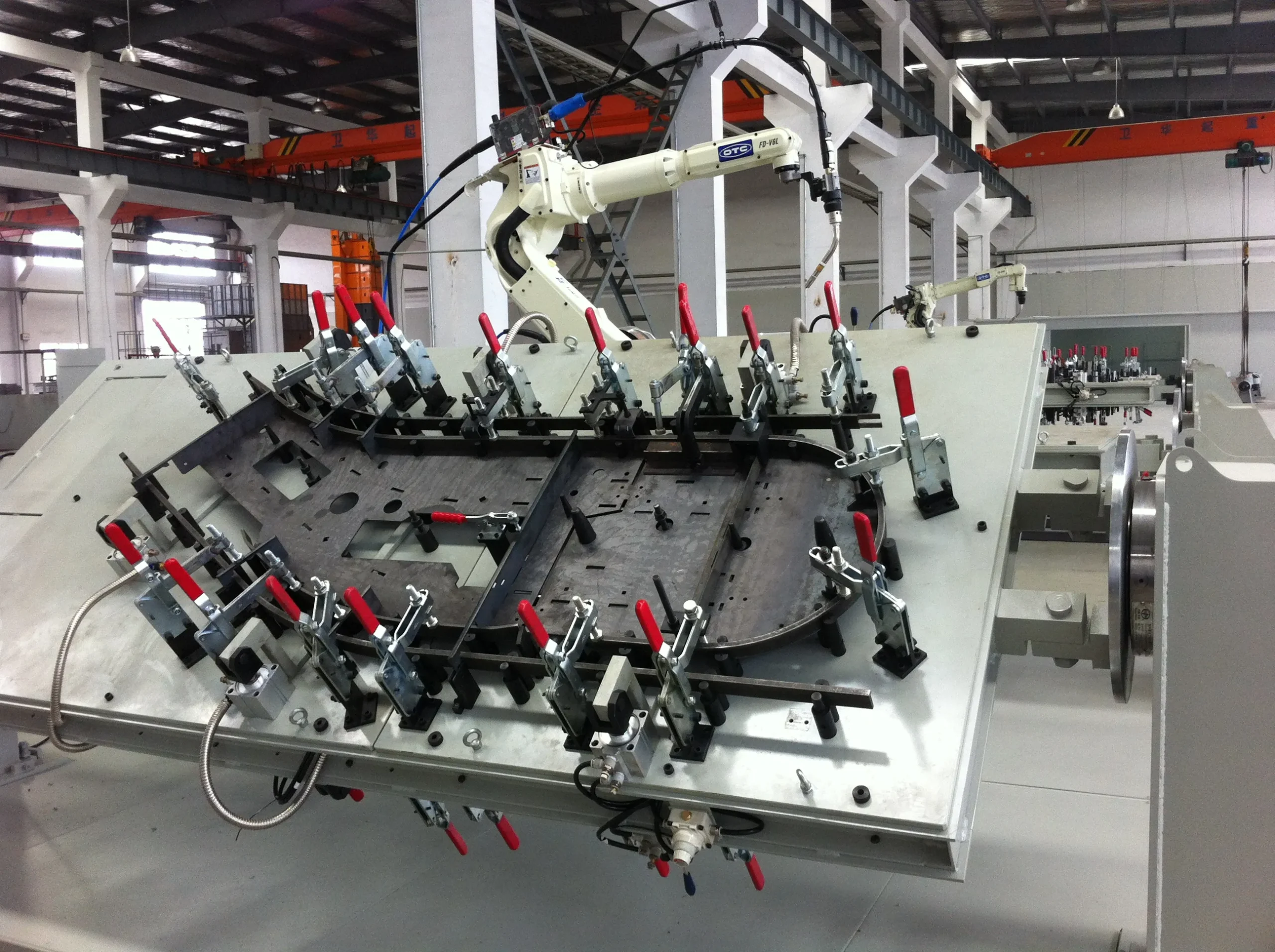

Our elevator side door welding line employs aerospace-grade robotics and AI-powered calibration to produce doors that exceed EN 81-20 safety standards. Engineered for 0.1mm positional accuracy, the system ensures flawless welds on stainless steel frames, fire-rated panels, and corrosion-resistant alloy thresholds. Adaptive laser welding heads and real-time distortion control eliminate micro-cracks in load-bearing hinges and guide rails, guaranteeing 200,000+ cycle durability for high-traffic commercial elevators and high-rise residential systems.

Multi-Material Mastery for Code Compliance

Specializing in elevator industry requirements, our elevator side door welding production line seamlessly welds dissimilar materials-including galvanized steel for structural integrity, AISI 304 stainless for hygienic environments, and fireproof composite layers.Our elevator side door welding production line”s proprietary low-heat input welding preserves material properties in smoke-seal joints and flame-retardant door cores, while IoT-enabled process monitoring ensures compliance with ASME A17.1 and ISO 4346 standards for global elevator deployments.

Agile Manufacturing for Custom Door Configurations

From panoramic glass door frames to hospital-grade antibacterial panels, our modular welding cells adapt to diverse elevator designs in under 15 minutes. AI-driven systems auto-adjust for door widths ranging from 800mm to 1400mm, while digital twin simulations validate welding sequences for custom arched or double-sliding doors 50% faster. Energy-recovery inverters reduce power consumption by 35% during 24/7 production of doors for smart elevators with IoT access controls.

Zero-Tolerance Quality Assurance

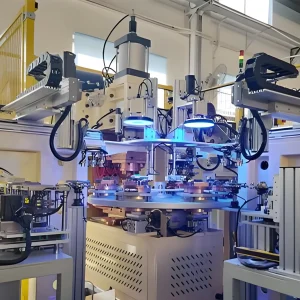

Our elevator side door welding line Integrated phased-array ultrasonic testing (PAUT) and 3D profilometry scan every weld seam at 25μm resolution. Machine learning algorithms cross-analyze 10,000+ parameters-including impact resistance and electromagnetic interference shielding-to auto-optimize welding protocols. Our elevator side door welding line’s blockchain-secured quality logs provide full traceability for critical components, ensuring audit-ready compliance with TÜV and CE certification requirements.

Sustainable Production for Vertical Transportation

Featuring VOC-free welding processes and closed-loop fume filtration, our elevator side door welding line reduces CO₂ emissions by 45% versus conventional methods. Recycled stainless steel is precision-welded into LEED-certified door assemblies, while hydrogen-powered preheating stations support net-zero manufacturing goals. Partner with us to build elevator side door welding line that combine uncompromising safety with eco-responsible innovation-scaling skylines sustainably.