Description

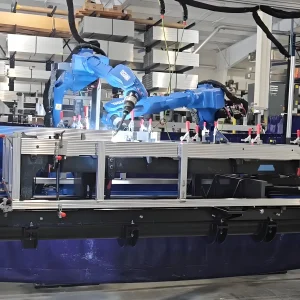

Advanced Automation for Precision Welding

Our elevator door panel welding production line integrates cutting-edge automation technology to ensure unparalleled precision and efficiency. Equipped with robotic welding arms and AI-driven quality control systems, the line delivers consistent weld seams, minimizing human error. Programmable logic controllers (PLCs) enable seamless coordination between material feeding, laser alignment, and multi-axis welding processes. Designed for high-volume manufacturing, this system reduces cycle times by 40% while maintaining ISO 3834 welding standards, our elevator door panel welding production line makes it ideal for mass production of elevator components.

Customizable Welding Solutions for Diverse Specifications

Tailored to accommodate stainless steel, galvanized steel, and aluminum alloys, our elevator door panel welding production line supports custom configurations for door panel thicknesses (0.8mm-3.0mm) and complex geometries. The modular design allows quick tooling changes between flat panels, embossed patterns, and fire-rated door variants. Integrated vision systems with 0.02mm positioning accuracy ensure perfect alignment for critical components like guide rails and lock brackets. Optional TIG/MIG welding modules cater to specific surface finish requirements, guaranteeing compliance with EN 81-20 safety regulations.

Smart Quality Assurance Ecosystem

Real-time monitoring systems track 18+ welding parameters (current, voltage, speed) while thermal imaging cameras detect micro-defects invisible to the naked eye. Post-weld treatments include automated grinding stations and non-destructive testing (NDT) using ultrasonic scanners. All data syncs with our MES platform, generating traceable digital reports for every batch – a critical feature for OEMs requiring IATF 16949-certified documentation.

Energy-Efficient Production Architecture

Our elevator door panel welding production line osuptimizes energy conmption through regenerative power systems and servo-driven mechanisms, reducing energy costs by 30% versus conventional lines. Compact layout planning (15% smaller footprint) with overhead material conveyors maximizes floor space utilization. Our elevator door panel welding production line equips optional solar-compatible power modules and VOC filtration systems align with LEED certification requirements, supporting sustainable manufacturing practices for eco-conscious clients.

Turnkey Integration & Global Support

From blueprint to operational deployment, we provide end-to-end solutions including factory layout simulation, operator training, and preventive maintenance planning. Remote diagnostics via IIoT platforms enable 24/7 technical support across global time zones. All systems come with CE/UL certification and are compatible with Industry 4.0 frameworks, ensuring seamless integration with existing smart factory infrastructures. Annual productivity guarantees and <0.3% defect rate commitments underscore our confidence in this state-of-the-art welding solution.