Description

Precision Clamping for Critical Suspension Components

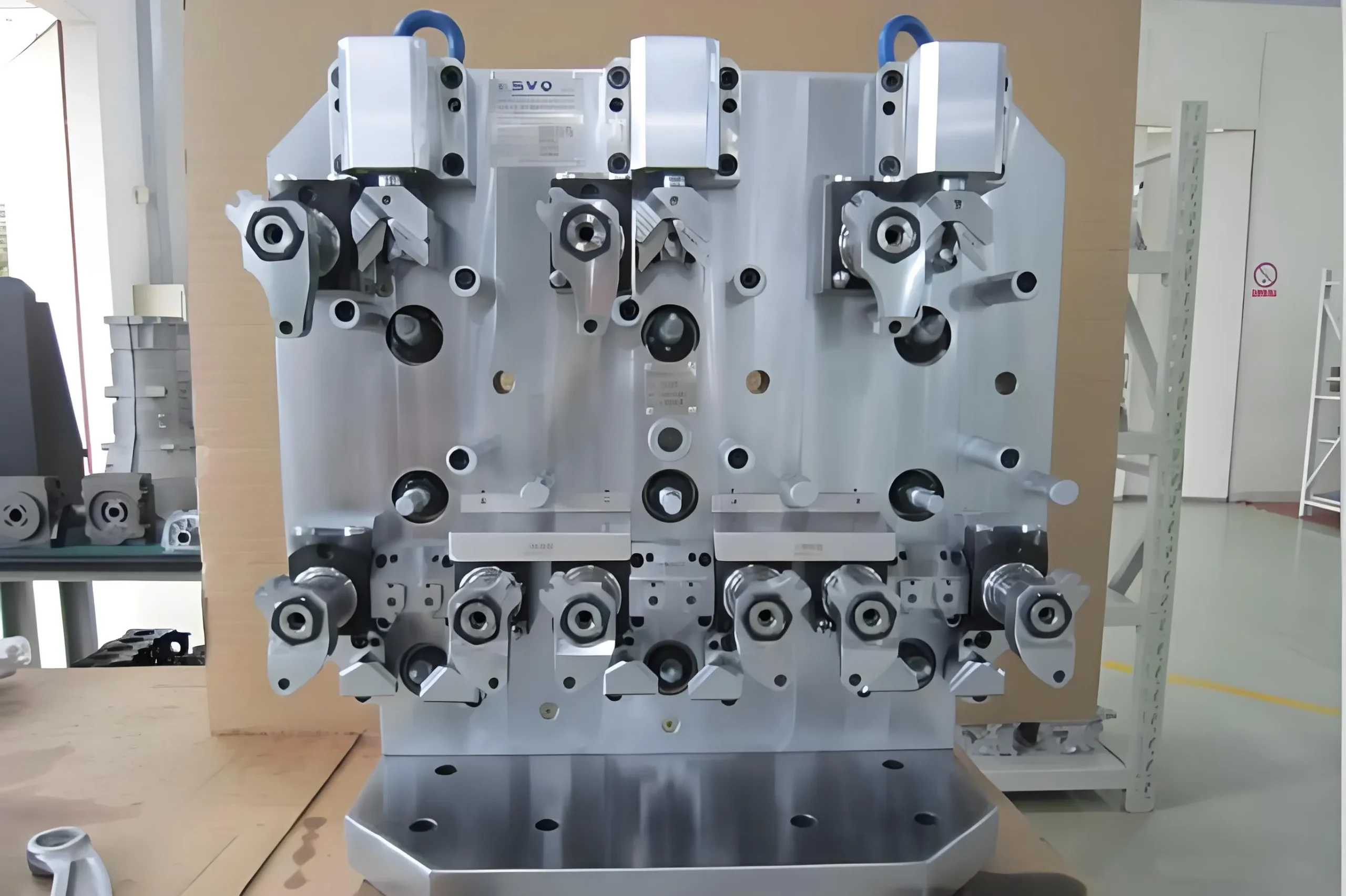

Our control arm welding fixtures guarantee micron-level accuracy (±0.03mm) for automotive suspension arms, ensuring perfect alignment of forged steel, aluminum, and composite assemblies. Hardened tool steel construction with CNC-machined locators secures critical joints like bush housings, ball stud mounts, and pivot points. Integrated laser alignment systems validate component positioning pre-weld, eliminating misalignment risks in high-stress applications. Compliant with IATF 16949 and ISO 9013 standards, these fixtures deliver consistent weld quality for EV chassis and heavy-duty truck suspension systems.

Modular Design for Multi-Model Flexibility

Engineered for mixed-model production, our control arm welding fixture feature quick-swap modules that adapt to 50+ control arm variants-from compact car A-arms to off-road double-wishbone designs-in under 5 minutes. Adjustable hydraulic clamps accommodate material thicknesses from 3mm to 25mm, while RFID-enabled tooling automates recipe selection for stamped, cast, or hybrid components. Optional rotary axis attachments enable 360° access for robotic MIG/TIG welding, boosting productivity by 35% in high-volume plants.

Smart Defect Prevention & Durability

Real-time force sensors detect clamping pressure deviations, preventing weld distortion during high-current cycles. Copper-tungsten contact surfaces resist spatter buildup, while water-cooled clamps maintain thermal stability in 24/7 operations. Post-weld CMM compatibility ensures dimensional accuracy within 0.05mm across 15+ tolerance zones. Built to withstand 10+ years of industrial use, IP67-rated components ensure reliability in harsh manufacturing environments.

Ergonomic & Sustainable Engineering

Low-profile, cobot-compatible design reduces operator fatigue by 40% with ergonomic loading heights and AR-guided workflows. Energy-efficient servo clamps consume 30% less power than pneumatic systems, while integrated fume extraction ports comply with OSHA 1910.252 safety standards. Recyclable aluminum frames and RoHS-compliant coatings align with automotive sustainability mandates for carbon-neutral production.

Custom Solutions & Global Support

From 3D scanning to fixture prototyping, we deliver tailored solutions for multi-material control arms, including hybrid steel-aluminum joints and CFRP reinforcements. On-site GD&T validation and ASME Y14.5-2018 certification ensure aerospace-grade precision. IIoT-enabled remote diagnostics provide 24/7 predictive maintenance, while lifetime access to digital twin simulations optimizes fixture performance. CE/UL-certified with 98% first-pass yield guarantees, our fixtures empower Tier 1 suppliers to reduce rework costs by 60% while scaling production for global OEMs.