Description

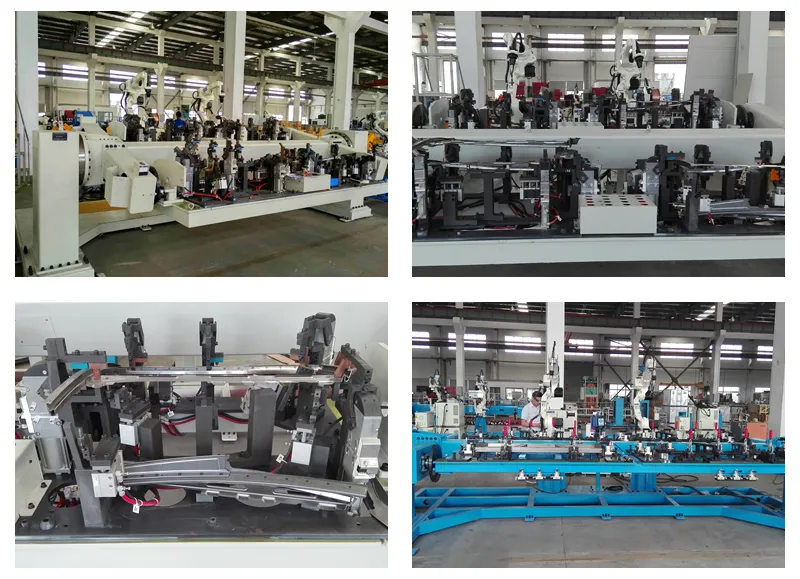

Precision-Driven Welding Technology

Our Car seat welding production line integrates state-of-the-art robotic welding arms and laser-guided positioning systems to ensure micron-level accuracy. Utilizing advanced resistance spot welding (RSW) and MIG/MAG welding processes, we achieve consistent, high-strength joints that meet IATF 16949 and OEM-specific standards. Automated seam tracking minimizes material waste while maintaining structural integrity for crash-tested safety.

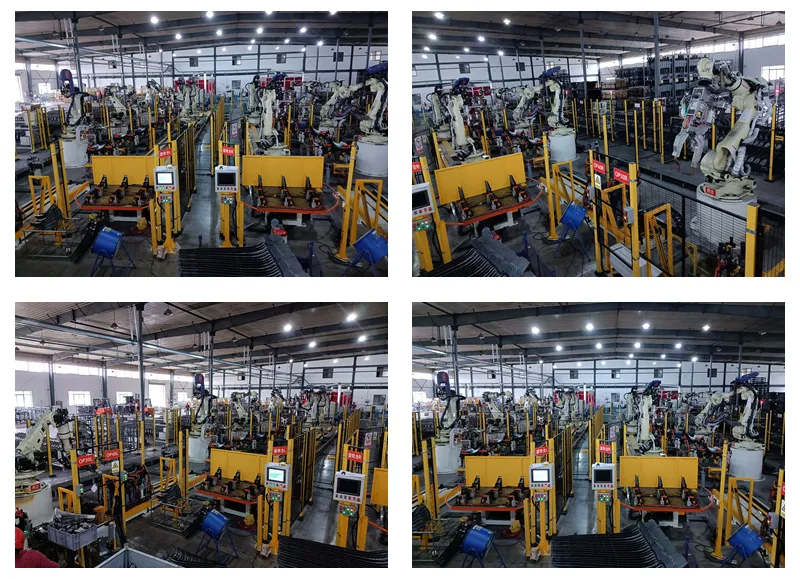

Modular Automation for Scalability

Engineered with flexible PLC-controlled modules, our Car seat welding production line adapts to diverse seat designs – from bucket seats to split benches. Smart conveyor systems synchronize welding robots, clamp fixtures, and quality inspection stations, achieving a cycle time of ≤45 seconds per unit. IoT-enabled predictive maintenance reduces downtime by 30%, ensuring 24/7 operational readiness for high-volume orders.

Ergonomic Quality Assurance

Every welded seat frame undergoes rigorous multi-stage testing: AI-powered vision systems detect micro-fractures, while torsion testers validate load capacities up to 2,500N. Our patented distortion-control algorithm compensates for thermal expansion during welding, guaranteeing ±0.2mm dimensional accuracy. Compliance with FMVSS 207/210 and Euro NCAP standards is systematically verified.

Sustainable Manufacturing Ecosystem

The Car seat welding production line features energy recovery systems that repurpose 85% of welding heat, reducing carbon footprint by 40% versus conventional setups. Fume extraction units with HEPA-14 filtration maintain OSHA-compliant air quality. Recyclable jig designs and wire-feeder optimization cut material consumption by 18%, aligning with circular economy principles.

Custom-Tailored Integration

From prototyping to full-scale production, we deliver turnkey solutions: 3D simulation verifies line layouts pre-deployment, while our proprietary Welding Parameter Cloud (WPC) enables real-time adjustments for exotic alloys or lightweight composites. Backed by 15+ years of Tier 1 supplier experience, we provide localized technical support and annual throughput guarantees up to 500,000 units.