Description

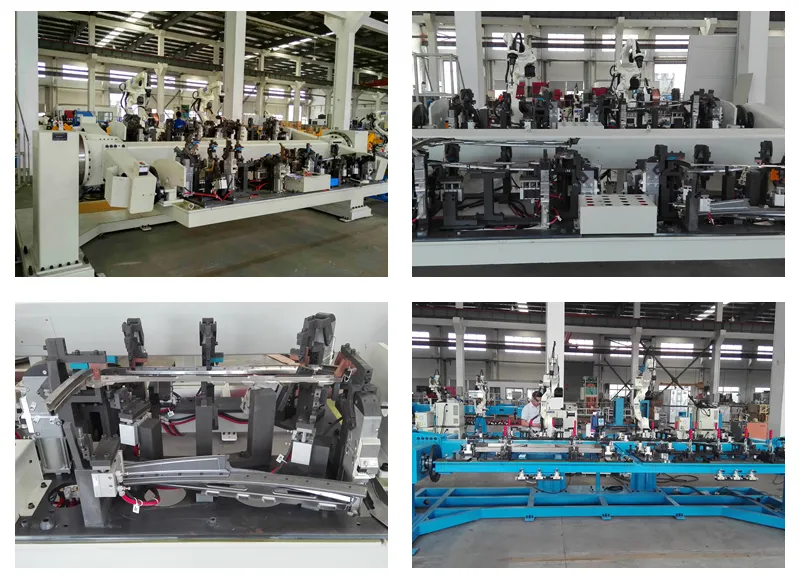

Precision Engineering for Modern Assembly

Our Car seat fixtures are CNC-machined with ±0.02mm tolerance, ensuring perfect alignment for seat frame welding and component integration. Engineered for compatibit fixtureslity with KUKA and Fanuc robotic arms, these modular jigs reduce assembly line changeover time by 40%. ISO/TS 16949-certified clamping systems prevent part deformation during high-pressure stamping processes.

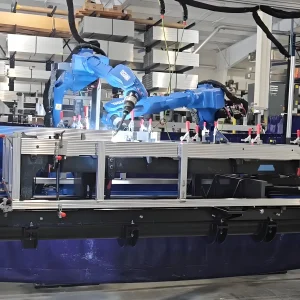

Ergonomic Multi-Material Compatibility

From lightweight aluminum alloys to advanced carbon fiber composites, our Car seat fixtures systems handle 18+ material combinations. Patented vacuum suction units and electro-permanent magnet bases enable simultaneous processing of metal brackets and polymer trim components. Features integrated coolant channels for thermal management during extended production runs.

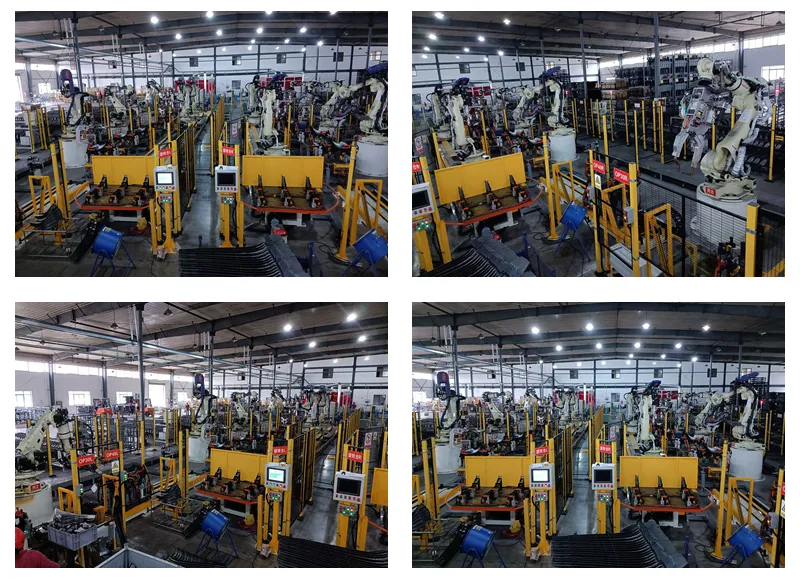

Smart Industry 4.0 Integration

IoT-enabled fixtures with embedded sensors provide real-time pressure mapping and weld quality analytics. Bluetooth-connected clamping force monitors sync with plant MES systems, achieving 99.7% defect-free assembly rates. Compatible with digital twin simulations for virtual line validation before physical deployment.

Customizable Scalable Solutions

Choose from 200+ standardized modular units or request bespoke designs for prototype seat development. Our rapid configuration service delivers project-specific jigs within 72 hours, complete with GD&T-certified documentation. All units feature universal mounting patterns for seamless integration with existing conveyor systems.

Global Compliance & Lifetime Support

Manufactured in IATF 16985-certified facilities, our fixtures meet EU Machinery Directive 2006/42/EC and OSHA safety standards. Includes 10-year structural warranty with free annual calibration services. On-site technicians available for installation training and predictive maintenance program setup worldwide.