Description

High-Precision Exhaust Pipe Clamping Solutions

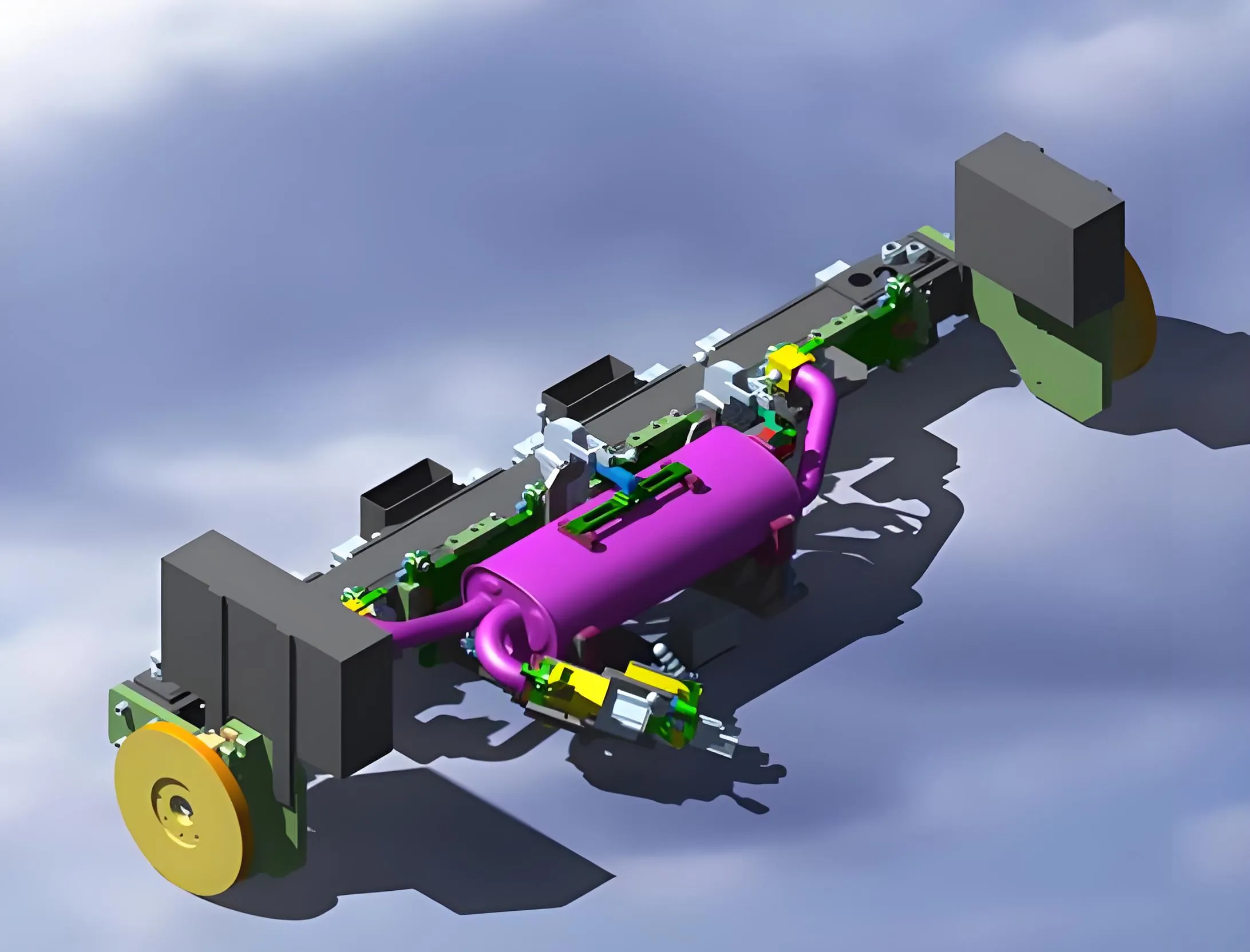

Our exhaust pipe clamping fixtures are engineered for ±0.05mm repeatability, ensuring perfect alignment during welding, bending, and assembly processes. CNC-machined from aerospace-grade aluminum and hardened steel, these jigs withstand temperatures up to 650°C while resisting exhaust gas corrosion. Modular designs accommodate pipes from 20mm motorcycle exhausts to 300mm industrial ducting, with vacuum-sealed quick-release mechanisms enabling tool-free changeovers in under 90 seconds.

Universal Compatibility & Adaptive Design

Customize clamping profiles for any material – stainless steel, titanium, or composite exhaust pipes – through interchangeable V-block inserts. Patented radial adjustment arms allow 360° multi-angle fixation, ideal for complex mandrel bends and catalytic converter interfaces. Integrated coolant channels prevent thermal distortion during high-frequency TIG welding, maintaining dimensional accuracy across 100,000+ cycles.

Smart Quality Control Integration

Embedded IoT sensors monitor clamping force (0-5000N adjustable) and parallelism in real time, syncing data with factory MES systems via Bluetooth 5.0. Optional laser alignment modules automatically detect pipe ovality deviations, triggering alerts when tolerances exceed ISO 15786-3 standards. All fixtures include QR-coded traceability certificates for IATF 16949 automotive compliance audits.

Ergonomic Efficiency Boost

Lightweight carbon fiber construction reduces operator fatigue by 40% compared to traditional clamps. Magnetic nesting bases allow single-hand operation, while anti-spatter nano-coating minimizes post-process cleaning. Compatible with KUKA/Yaskawa robotic arms, our Exhaust pipe clamp fixtures cut cycle times by 25% through synchronized positioning and automated toolpath calibration.

Lifetime Optimization Services

Access our 3D fixture configurator to design bespoke clamping solutions online, with instant DFM feedback. On-site calibration services and preventive maintenance kits ensure peak performance. Request a free clamping force analysis today – leverage our 15-year expertise to eliminate exhaust system rework and achieve zero-defect production goals.