Description

Automotive-Grade Precision Welding Systems

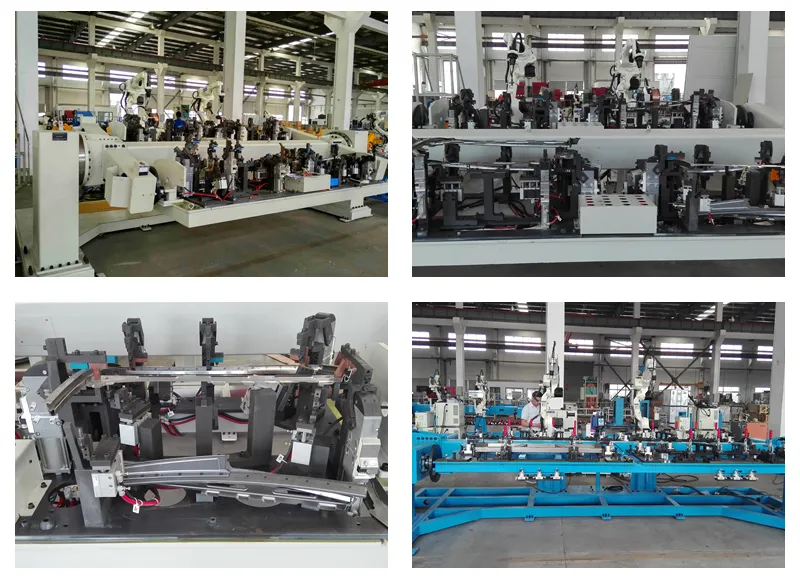

Our car door welding production line integrates robotic automation with AI-driven process control to deliver flawless welds for modern vehicle doors. Engineered for high-mix manufacturing, this system handles steel, aluminum, and composite materials with sub-millimeter accuracy, ensuring structural integrity for crash-rated door frames. Featuring adaptive laser welding heads and real-time seam tracking, our car door welding production line achieves 99.95% defect-free joints while maintaining cycle times under 45 seconds per door assembly-ideal for EV and luxury automotive OEMs.

Multi-Material Compatibility for Next-Gen Vehicles

Designed to address evolving automotive trends, our car door welding production line seamlessly welds dissimilar materials like ultra-high-strength steel (UHSS) and aluminum alloys for lightweight door architectures. Proprietary hybrid welding technology combines resistance spot welding with friction stir processes, eliminating thermal distortion in complex multi-layer door panels. our car door welding production line has Integrated cooling stations and AI-powered parameter optimization ensure consistent quality across hybrid and electric vehicle door production.

Agile Manufacturing for Custom Door Designs

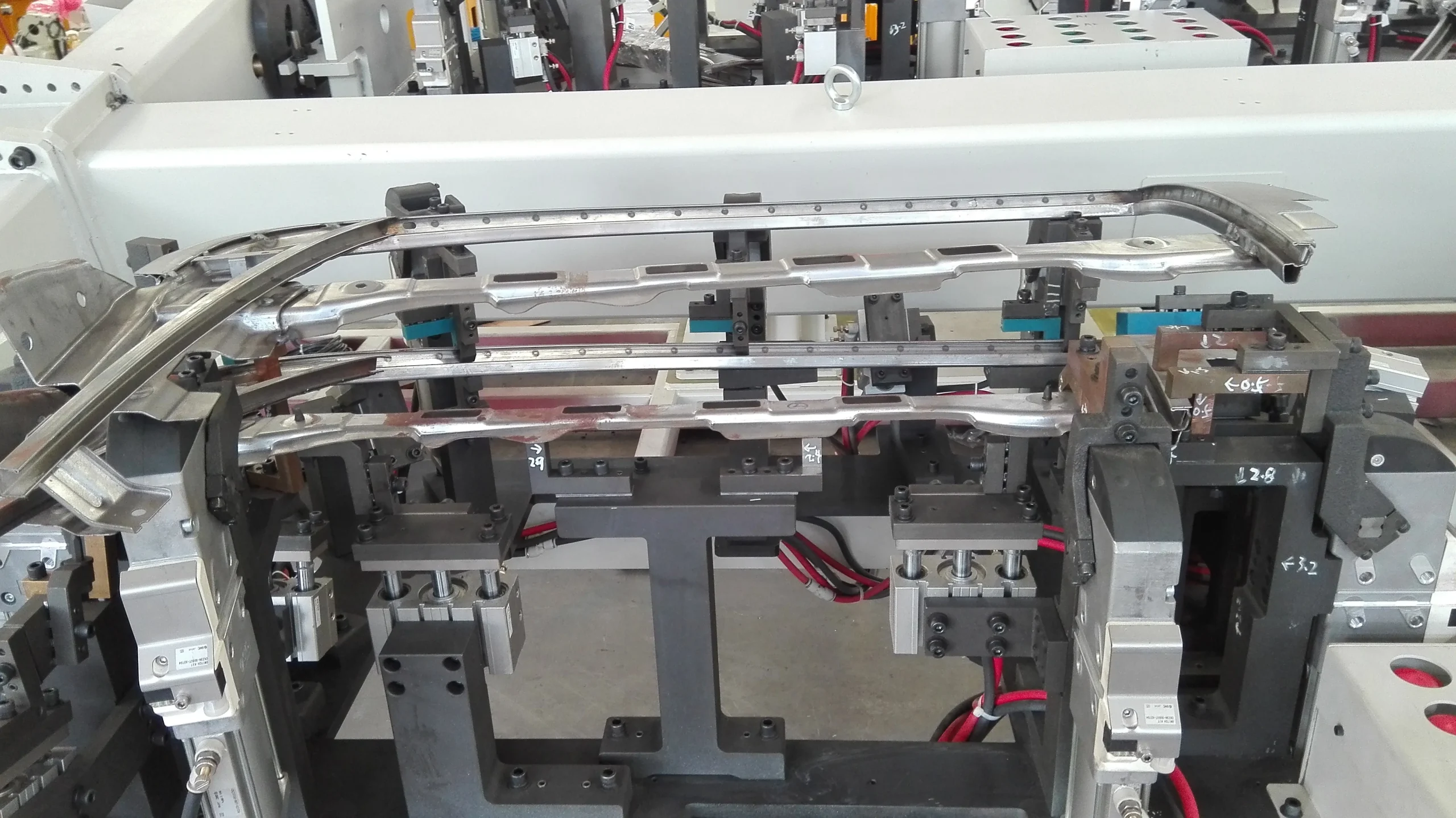

From frameless coupe doors to reinforced SUV panels, our car door welding production line welding cells enable rapid retooling for diverse automotive designs. Programmable EOAT (End-of-Arm Tooling) adapts to curved surfaces and hidden weld seams in under 15 minutes, while digital twin simulations validate welding sequences for new door prototypes 60% faster than traditional methods. car door welding production line’s IoT-enabled energy recovery systems reduce power consumption by 35% during high-volume production runs.

Zero-Defect Quality Assurance Protocol

Our car door welding production line equipped with 3D laser scanners and phased-array ultrasonic testing, our line performs 360° weld inspections at 0.02mm resolution. Machine learning algorithms cross-analyze 12,000+ data points per door-including tensile strength and corrosion resistance metrics-to auto-correct welding parameters. car door welding production line’s blockchain-secured quality records comply with IATF 16949 standards, providing auditable traceability for every door assembly in autonomous vehicle and premium car programs.

Sustainable Automotive Manufacturing Solutions

Featuring VOC-free welding processes and closed-loop fume filtration, our car door welding production line reduces CO₂ emissions by 50% compared to conventional door welding systems. Our car door welding production line recyclable aluminum spatter collection systems recover 98% of metal waste, while hydrogen-powered preheating stations support carbon-neutral production goals. Partner with us to manufacture doors for electric and hybrid vehicles that meet both automotive safety standards and global ESG commitments.