Description

High-Strength Crash Beam Welding Solutions

Our Automobile anti-collision beam welding production line specializes in manufacturing ultra-durable automotive crash beams, utilizing advanced laser welding and CMT (Cold Metal Transfer) technologies. Engineered for impact-critical components, we achieve consistent penetration depth (±0.15mm) on high-strength steels (HSS), boron alloys, and aluminum grades (5xxx/6xxx series), ensuring compliance with IIHS and Euro NCAP safety standards.

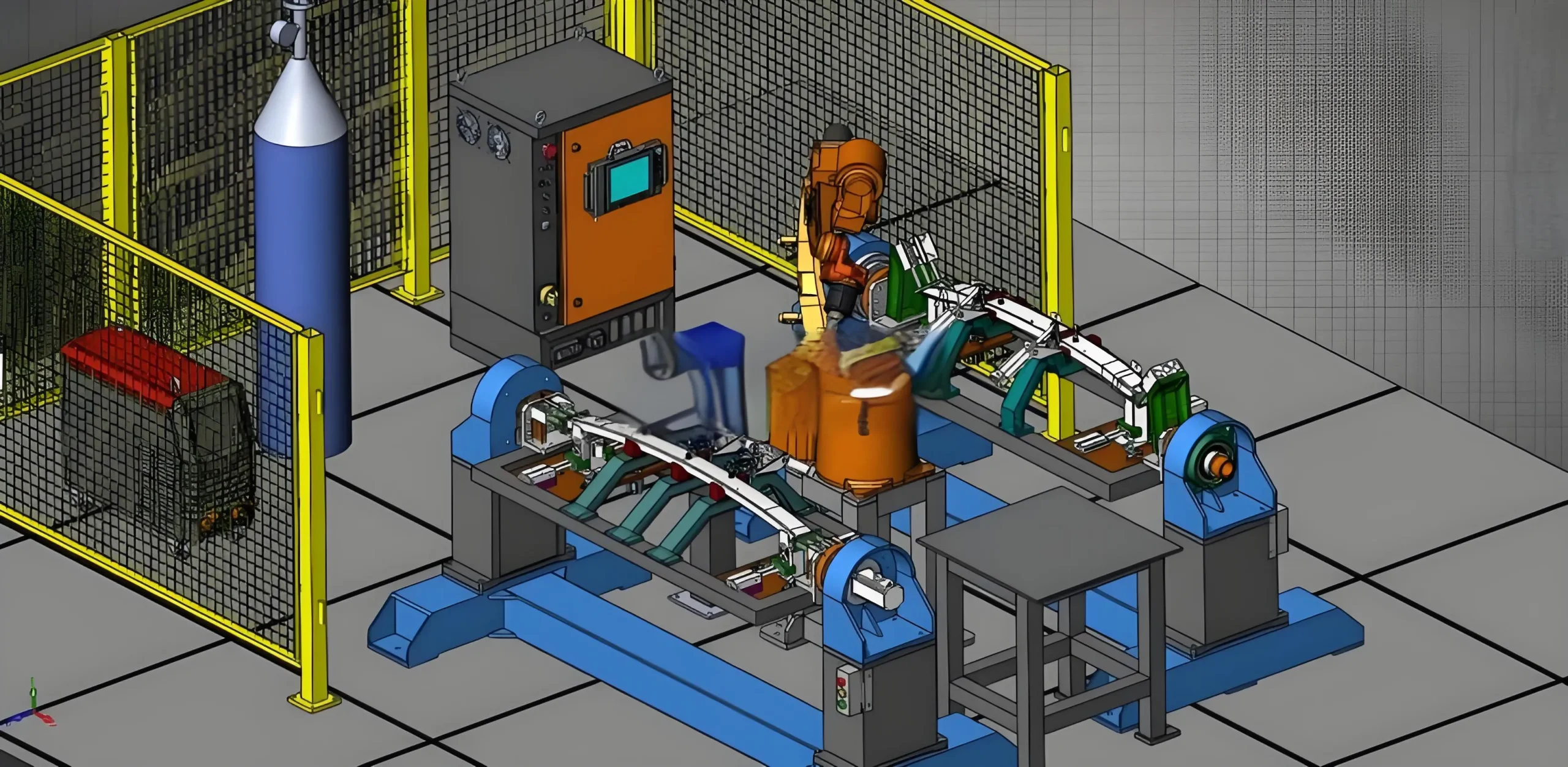

Robotic Multi-Process Welding Cells

Integrated robotic systems combine spot welding, arc brazing, and hybrid laser-MIG processes for complex crash beam geometries. Equipped with adaptive force control (500N accuracy) and real-time thermal imaging, our Automobile anti-collision beam welding production line prevents material warping while maintaining tensile strengths exceeding 1,200 MPa. Automated fixture switching supports 15+ beam variants within a single cycle.

Crash-Tested Production Precision

Certified welding processes validate beam integrity through 50+ mph simulated collision tests. Our lines incorporate inline hardness testing (Rockwell C-scale) and AI-powered defect detection (99.98% accuracy) to guarantee weld consistency across ±0.2mm positional tolerance. Full MES integration ensures traceability from raw material to final assembly.

Agile Manufacturing for OEM Demands

Scalable from prototype batches (10 beams/hr) to mass production (200 UPH), our modular systems adapt to front/rear beam designs and multi-material structures. Proprietary post-weld stress-relief modules enhance fatigue resistance, validated through 1 million+ cyclic load tests under -40°C to 150°C conditions.

Smart Welding Line Integration

Industry 4.0-ready systems feature energy-efficient DC inverters (35% power savings) and predictive maintenance via IoT sensors. Digital twin technology simulates crash dynamics pre-production, optimizing weld patterns for energy absorption efficiency. Compliant with IATF 16949 and ASTM E8/E384 standards for automotive structural welding.