Description

Precision Welding Solutions for Aluminum Alloy Shelving Systems

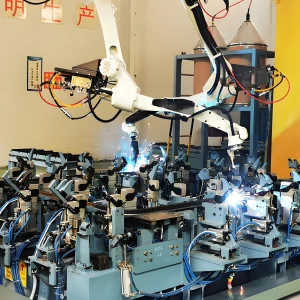

Our Aluminum alloy shelf welding production line combines cutting-edge automation with specialized engineering to deliver high-strength, lightweight, and corrosion-resistant storage solutions. Designed for industrial, commercial, and logistics applications, our systems employ robotic MIG/TIG welding and laser alignment technologies to ensure seamless joints and structural durability. Optimized for aluminum’s unique properties, the Aluminum alloy shelf welding production line minimizes heat distortion while maximizing throughput, making it ideal for manufacturing heavy-duty warehouse racks, retail displays, and modular shelving units.

Automated Efficiency for Scalable Production

Boost productivity with our fully automated welding line tailored for aluminum shelving manufacturing. Equipped with multi-axis robotic arms and AI-driven vision systems, our setup guarantees consistent weld quality across high-volume orders. Real-time monitoring via IoT sensors adjusts parameters like temperature and wire feed speed, ensuring compliance with load-bearing standards (e.g., ANSI/MHIA). Reduce labor costs by 50% and achieve 30% faster cycle times, enabling rapid scalability for custom designs-from compact garage shelving to industrial pallet racks.

Customizable Welding Systems for Diverse Designs

Whether crafting bolt-free cantilever racks or adjustable bolt-together shelving, our production line adapts to your unique specifications. We support welding for varied aluminum alloys (6061, 6063, etc.), thicknesses (1mm to 8mm), and geometries-including angles, channels, and perforated panels. Modular fixtures and programmable welding paths allow quick transitions between product lines, while friction-stir welding options enhance joint integrity for high-stress applications. Partner with us to create shelving systems that balance aesthetics, functionality, and compliance.

Rigorous Quality Control & Eco-Friendly Practices

Every aluminum shelving unit undergoes stringent quality checks via X-ray inspection, tensile testing, and 3D scanning to verify dimensional accuracy and weld integrity. Our sustainable production line prioritizes energy-efficient inverters and recycled aluminum materials, reducing waste by 25% and energy consumption by 20%. Certified to ISO 14001 and ISO 9001 standards, we ensure eco-conscious manufacturing without compromising the 10,000+ cycle lifespan expected from premium shelving systems.

End-to-End Technical Support & Innovation

From initial design consultation to post-installation maintenance, we provide comprehensive support for your welding operations. Our team offers training on AI-powered predictive maintenance tools and AR-assisted weld path optimization, ensuring seamless integration into your facility. With R&D focused on hybrid welding technologies and smart factory integration, we future-proof your investment. Choose our turnkey solutions to transform raw aluminum into market-ready shelving with unmatched precision, speed, and ROI.