Description

High-Strength Welding Solutions for Agricultural Machinery

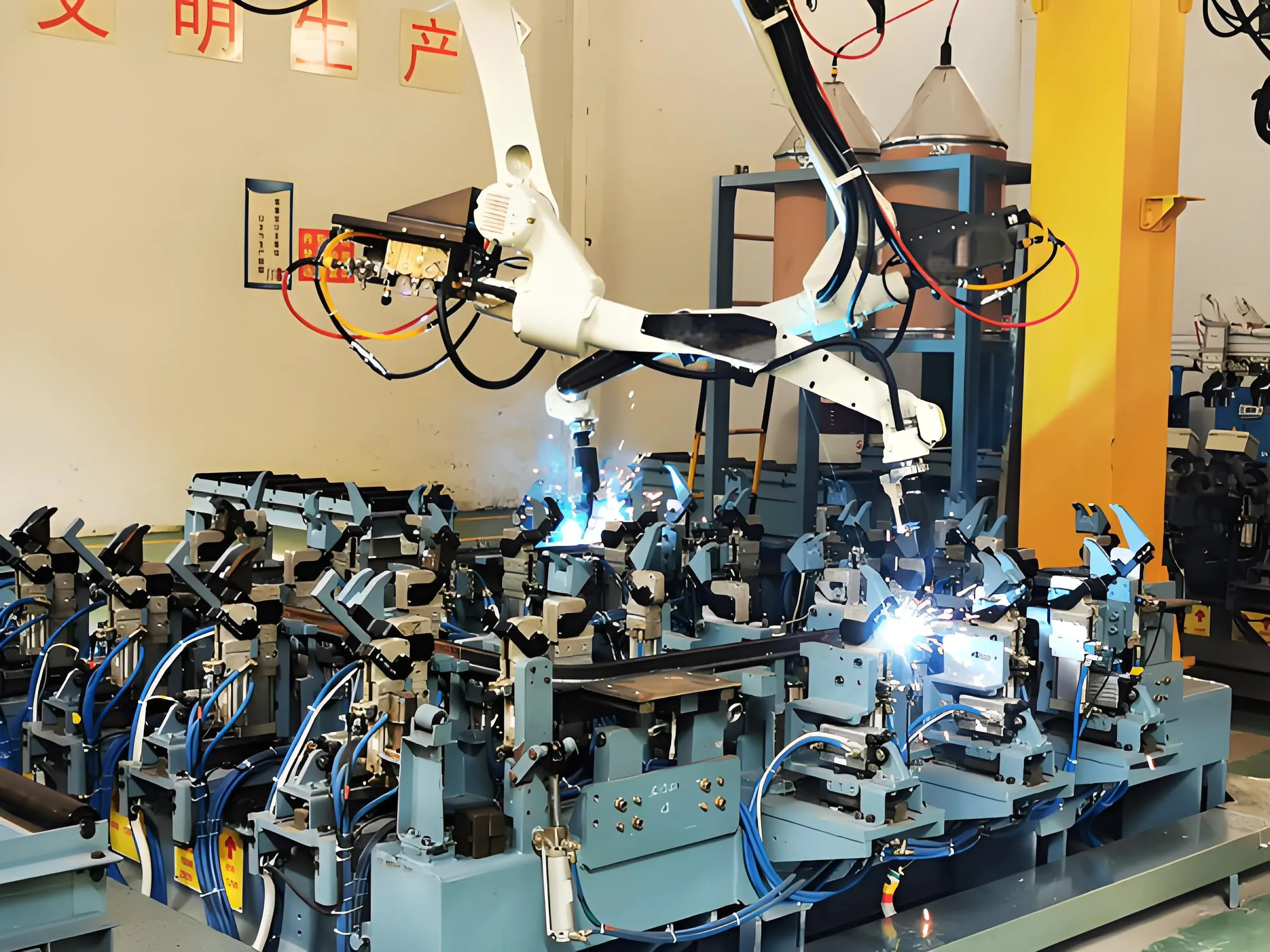

Our Agricultural machinery welding production line for agricultural machinery delivers unmatched durability and precision, engineered to withstand the rigorous demands of farming equipment. From plows and tillers to harvesters and tractor components, our systems utilize heavy-duty robotic MIG welding, submerged arc welding (SAW), and adaptive CNC controls to handle thick steel plates, complex geometries, and high-stress joints. Designed for corrosion resistance and fatigue strength, our Agricultural machinery welding production line ensure long-lasting performance in harsh outdoor environments, empowering farmers with reliable, season-ready machinery.

Automated Efficiency for Robust Farm Equipment

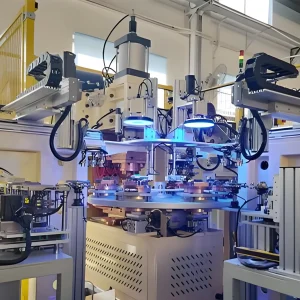

Transform your agricultural manufacturing with our fully automated welding lines, tailored for high-volume and custom farm machinery production. Equipped with multi-axis robots and AI-powered vision systems, our setup achieves consistent, high-speed welding on components like cultivator frames, seeders, and balers. IoT-enabled sensors monitor weld penetration, temperature, and material alignment in real time, reducing defects by 35% and slashing production downtime. Ideal for OEMs, our solutions cut labor costs by 40% while scaling seamlessly to meet seasonal demand spikes.

Customized Welding for Diverse Farming Applications

Whether welding rugged harvester attachments or lightweight irrigation systems, our production line adapts to your unique needs. We support welding for carbon steel, stainless steel, and wear-resistant alloys, accommodating thicknesses from 3mm to 25mm. Modular fixtures and programmable welding paths enable quick transitions between equipment types-from rotary tillers to grain silo brackets. Advanced processes like laser-hybrid welding enhance precision for intricate parts, ensuring compliance with AGMA and ISO 5687 standards for agricultural machinery safety.

Quality Assurance Built for Extreme Conditions

Every weld undergoes rigorous testing to endure the toughest field operations. Our multi-stage inspection protocol includes ultrasonic testing, stress analysis, and salt-spray corrosion checks, guaranteeing structural integrity and longevity. Energy-efficient inverters and recycled steel materials align with sustainable farming practices, reducing energy use by 20% and waste by 30%. Certified to ISO 9001 and ISO/TR 12603, we ensure your equipment meets global agricultural industry benchmarks.

End-to-End Support for Smart Farming Innovation

Beyond production, we provide comprehensive services-from facility layout design to operator training and AI-driven predictive maintenance. Our R&D team integrates AR-assisted weld simulations and machine learning to optimize workflows for next-gen smart farming tools. Whether upgrading legacy systems or launching a new line, our turnkey solutions ensure rapid ROI and adaptability to evolving agritech trends. Partner with us to build farming equipment that combines brute strength with precision engineering.