Wid Automation's welding robot workstations combine precision, AI technology, and versatility to automate tasks, boost efficiency, and enhance safety across various industries.

Our Agricultural machinery welding production line for agricultural machinery delivers unmatched durability and precision, engineered to withstand the rigorous demands of farming equipment. From plows and tillers to harvesters and tractor components, our systems utilize heavy-duty robotic MIG welding, submerged arc welding (SAW), and adaptive CNC controls to handle thick steel plates, complex geometries, and high-stress joints.

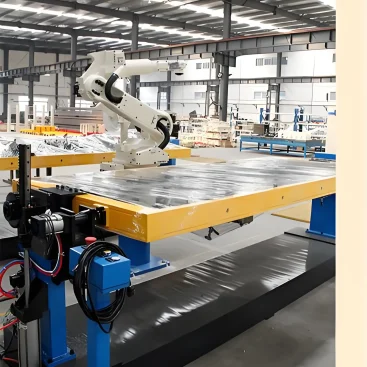

Our Aluminum alloy shelf welding production line combines cutting-edge automation with specialized engineering to deliver high-strength, lightweight, and corrosion-resistant storage solutions. Designed for industrial, commercial, and logistics applications, our systems employ robotic MIG/TIG welding and laser alignment technologies to ensure seamless joints and structural durability.

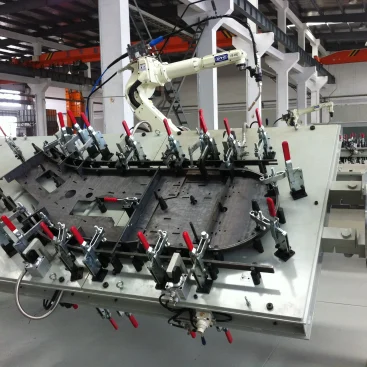

Our swing arm welding production line is engineered for precision fabrication of construction machinery booms, cranes, and excavator arms. Utilizing robotic MIG/MAG welding systems with adaptive arc sensing, it handles steel plates from 10mm to 50mm thickness while maintaining weld integrity under extreme loads.

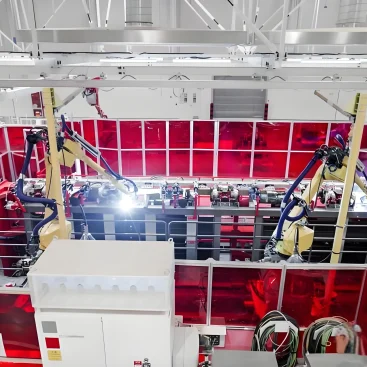

Our elevator door panel welding production line integrates cutting-edge automation technology to ensure unparalleled precision and efficiency. Equipped with robotic welding arms and AI-driven quality control systems, the line delivers consistent weld seams, minimizing human error.

Our elevator side door welding line employs aerospace-grade robotics and AI-powered calibration to produce doors that exceed EN 81-20 safety standards. Engineered for 0.1mm positional accuracy, the system ensures flawless welds on stainless steel frames, fire-rated panels, and corrosion-resistant alloy thresholds.

Our energy storage box welding production line combines robotic precision and AI-driven automation to manufacture robust, weatherproof battery enclosures for grid-scale and residential energy storage. Engineered for heavy-duty steel frames and corrosion-resistant aluminum housings, this system achieves ±0.15mm weld accuracy, ensuring airtight seals for IP66-rated enclosures.

Our Smart home welding production line integrates cutting-edge robotics, IoT-enabled systems, and AI-driven precision to revolutionize the manufacturing of smart home devices. Designed for seamless scalability, this fully automated line ensures high-speed, error-free welding of components for IoT hubs, smart appliances, and connected home systems.

Our car lift welding production line is engineered to fabricate high-strength scissor lifts, two-post lifts, and hydraulic column systems with unmatched precision. Equipped with 6-axis robotic welding arms and adaptive seam tracking, it achieves ±0.1mm accuracy on steel plates up to 25mm thickness, ensuring structural integrity for lifts rated to 15,000 lbs.

Our Medical bed welding production line employs aerospace-grade aluminum alloys and servo-controlled clamping mechanisms to secure components with ±0.02mm repeatability. Designed for multi-model compatibility (SUV/sedan/electric vehicles), the modular system reduces changeover time by 60% through patented quick-release pins and RFID-tagged tooling.

Our steel shelving welding production line combines robotic precision with unmatched throughput, producing up to 1,200 shelving units per shift. Equipped with 6-axis welding robots and AI-driven path planning, it achieves ±0.1mm repeatability on beams, uprights, and braces.

Our storage holder welding production line combines industrial robotics, AI-driven precision, and IoT connectivity to manufacture heavy-duty storage systems with unmatched efficiency. This storage holder welding production line engineered for mass production of pallet racks, cantilever shelves, and modular storage frameworks, this fully automated line delivers 30% faster cycle times than conventional systems.

Jiangsu Wid automation Co.,Ltd

Complete Assembly | Integrated Workstation | Plug-and-Play | No On-Site Installation Required

© 2025 Jiangsu Wid Automation All Rights Reserved.

Designed by AdmarV