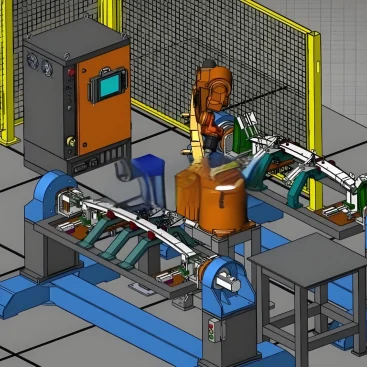

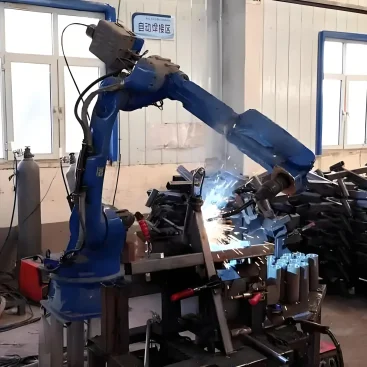

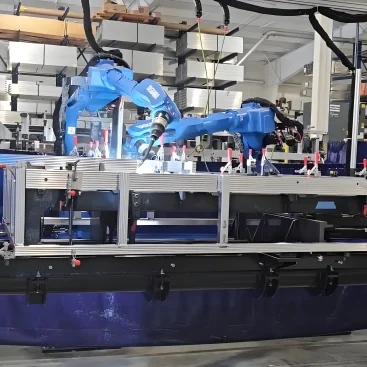

Wid Automation's welding robot workstations combine precision, AI technology, and versatility to automate tasks, boost efficiency, and enhance safety across various industries.

Certified welding processes validate beam integrity through 50+ mph simulated collision tests. Our lines incorporate inline hardness testing (Rockwell C-scale) and AI-powered defect detection (99.98% accuracy) to guarantee weld consistency across ±0.2mm positional tolerance. Full MES integration ensures traceability from raw material to final assembly.

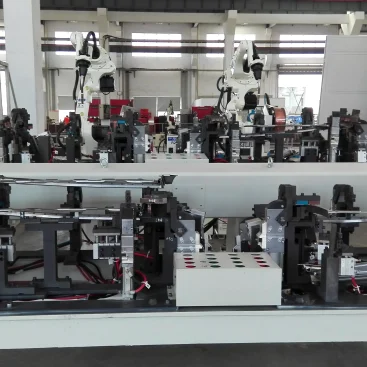

Our Automobile chassis welding production line integrates cutting-edge robotic systems with AI-powered quality control, delivering precision welding for unibody and frame structures. Featuring 6-axis industrial robots with laser-guided positioning, the system achieves ±0.1mm repeat accuracy, ensuring consistent weld seam quality across SUVs, EVs, and commercial vehicles.

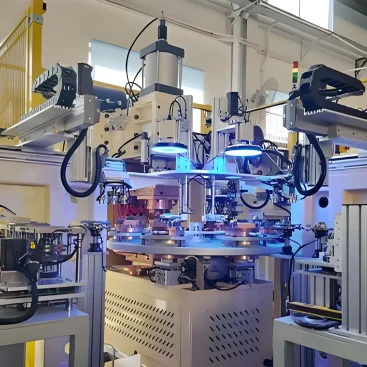

Our automotive body welding production line leverages advanced robotics and AI-driven control systems to deliver micron-level accuracy for high-strength vehicle body construction. Engineered for multi-material architectures—including ultra-high-strength steel (UHSS), aluminum alloys, and carbon-fiber composites—this fully automated line ensures flawless welds for crash-critical components like pillars, rocker panels, and roof structures.

Our two-wheeled vehicles production line combines precision engineering with cutting-edge automation to deliver unmatched quality and efficiency. Designed for motorcycles, bicycles, e-bikes, and scooters, our welding systems utilize robotic arms, laser welding technology, and AI-driven quality control to ensure seamless joints and structural integrity.

Maximize throughput with our fully integrated Subframe welding production line, featuring synchronized clamping fixtures and real-time seam tracking. The system processes 120+ subframes per hour with 6-axis robots, handling crossmembers, bushings, and suspension mounting points in a single cycle.

Our exhaust pipe welding production line integrates cutting-edge robotic welding systems and precision laser technology to deliver flawless, high-speed fabrication. Engineered for automotive, aerospace, and industrial applications, the fully automated workflow minimizes human intervention while ensuring consistent weld quality.

Our shock absorber welding production line delivers automotive-grade accuracy for high-stress components like strut housings, piston rods, and mounting brackets. Equipped with synchronized robotic MIG/TIG welding systems, it achieves ±0.05mm repeatability on materials ranging from carbon steel (2mm-12mm) to chrome-plated alloys.

Our car door welding production line integrates robotic automation with AI-driven process control to deliver flawless welds for modern vehicle doors. Engineered for high-mix manufacturing, this system handles steel, aluminum, and composite materials with sub-millimeter accuracy, ensuring structural integrity for crash-rated door frames.

Our Car seat welding production line integrates state-of-the-art robotic welding arms and laser-guided positioning systems to ensure micron-level accuracy.

Our shock absorber welding production line delivers automotive-grade accuracy for high-stress components like strut housings, piston rods, and mounting brackets. Equipped with synchronized robotic MIG/TIG welding systems, it achieves ±0.05mm repeatability on materials ranging from carbon steel (2mm-12mm) to chrome-plated alloys.

Jiangsu Wid automation Co.,Ltd

Complete Assembly | Integrated Workstation | Plug-and-Play | No On-Site Installation Required

© 2025 Jiangsu Wid Automation All Rights Reserved.

Designed by AdmarV