Wid Automation's welding robot workstations combine precision, AI technology, and versatility to automate tasks, boost efficiency, and enhance safety across various industries.

An automotive roof welding fixture is a specialized tool used in vehicle manufacturing to securely position and align a car’s roof panel during the welding process. Designed for precision, these fixtures ensure that the roof component is held in the correct orientation relative to other body parts, such as pillars, side panels, and crossmembers.

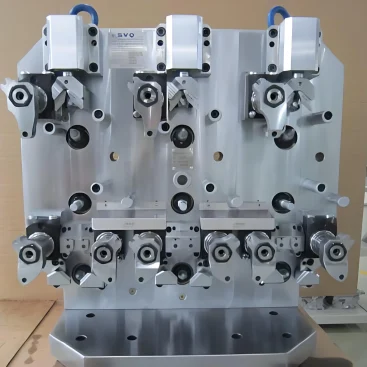

Our Car dashboard fixture employ aerospace-grade aluminum alloys and servo-controlled clamping mechanisms to secure components with ±0.02mm repeatability. Designed for multi-model compatibility (SUV/sedan/electric vehicles), the modular system reduces changeover time by 60% through patented quick-release pins and RFID-tagged tooling.

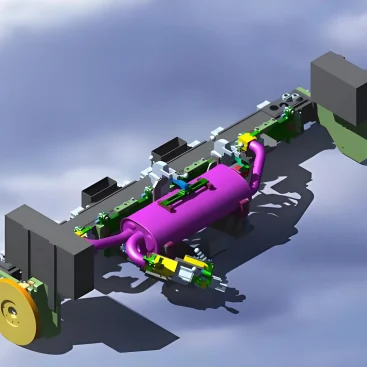

Our exhaust pipe clamping fixtures are engineered for ±0.05mm repeatability, ensuring perfect alignment during welding, bending, and assembly processes. CNC-machined from aerospace-grade aluminum and hardened steel, these jigs withstand temperatures up to 650°C while resisting exhaust gas corrosion.

Our Car seat fixtures are CNC-machined with ±0.02mm tolerance, ensuring perfect alignment for seat frame welding and component integration. Engineered for compatibit fixtureslity with KUKA and Fanuc robotic arms, these modular jigs reduce assembly line changeover time by 40%.

Our control arm welding fixtures guarantee micron-level accuracy (±0.03mm) for automotive suspension arms, ensuring perfect alignment of forged steel, aluminum, and composite assemblies. Hardened tool steel construction with CNC-machined locators secures critical joints like bush housings, ball stud mounts, and pivot points.

The structural backbone of a car subframe welding fixture is its robust frame, engineered from high-grade steel or reinforced aluminum alloys to endure extreme mechanical loads and thermal stresses during welding. The frame’s rigid design ensures dimensional stability, preventing flexing or vibration that could compromise alignment accuracy.

Jiangsu Wid automation Co.,Ltd

Complete Assembly | Integrated Workstation | Plug-and-Play | No On-Site Installation Required

© 2025 Jiangsu Wid Automation All Rights Reserved.

Designed by AdmarV