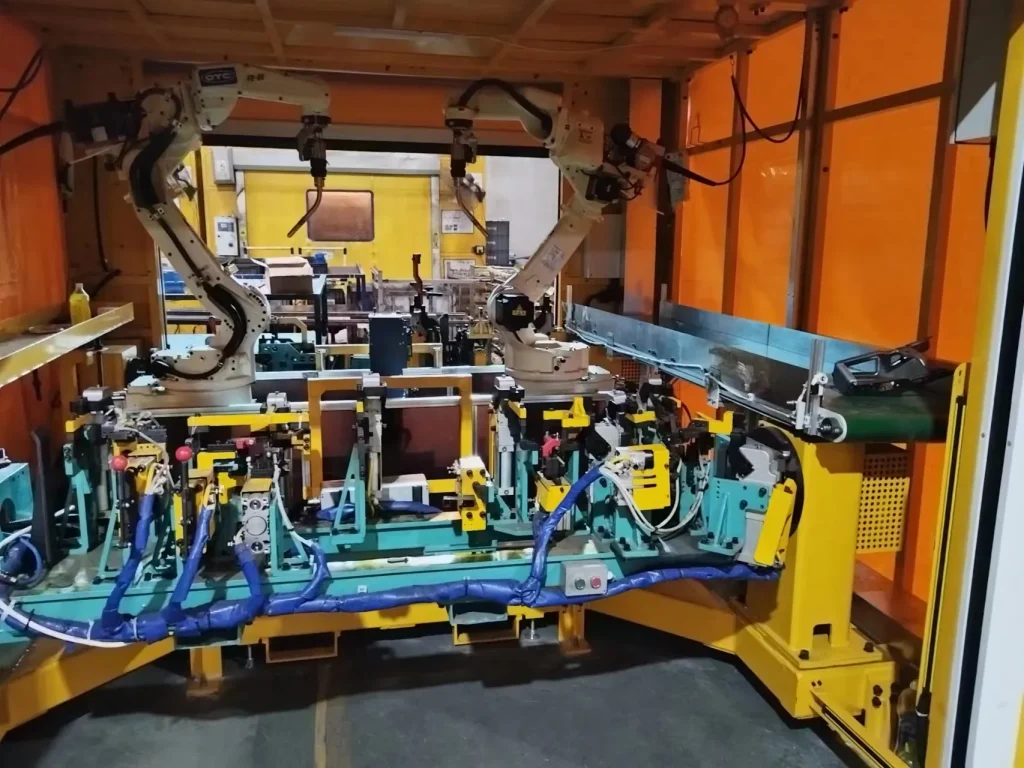

The intelligent instrument panel welding workstation integrates robot welding, visual positioning, quality inspection and other functions.

what makes us different

High-precision welding robot

6-axis linkage, repeated positioning accuracy ±0.05mm, and supports multiple welding processes (laser welding/arc welding).

Visual positioning system

Automatically identify the position of the instrument panel weld, dynamically compensate for deviations, and ensure accurate welding paths.

Flexible fixture tooling

Adapt to multiple models of instrument panels, fast changeover (≤5 minutes), and strong compatibility.

Intelligent monitoring platform

Real-time monitoring of welding parameters (current/voltage/temperature), traceable data, and automatic alarm for abnormalities.

Safety protection

Fully enclosed work area, equipped with grating and emergency stop device.Improve working environment and eliminate the impact of welding smoke on operators

Intelligent and efficient

Achieve ±0.1mm positioning accuracy, 30-60s cycle time, and over 99.5% welding pass rate with intelligent parameter adjustment and flexible process switching.

Choose us to make welding smarter and more efficient!

Industry-leading technology

Focus on installing workstations and production lines, integrating top robot brands such as Yaskawa, OTC, Fanuc, and Kuka to ensure efficient automation solutions.

Rich project experience

Many years of industry experience, successfully delivering a variety of complex R&D projects, and customers covering a wide range of fields.

Customized service

Flexible design according to needs, providing one-stop support from solutions to after-sales.

Professional team support

Technical experts provide full service and quick response to help you seamlessly upgrade intelligent welding production.

Jiangsu Wid automation Co.,Ltd

Complete Assembly | Integrated Workstation | Plug-and-Play | No On-Site Installation Required

© 2025 Jiangsu Wid Automation All Rights Reserved.

Designed by AdmarV